Squeezing soft materials: the mechanical properties of emulsions stabilised by solid particles

Soft Matter journal has published a paper that details a School research team's investigations into the mechanical properties of emulsions that are stabilized by micron-sized particles.

The team, based in the School's Institute for Condensed Matter and Complex Systems (ICMCS) included two undergraduate students: Louison Maurice, an exchange student from Lyon who is currently teaching Physics and Chemistry in a secondary school in France, and Ryan Maguire from Edinburgh who is now a Nuclear Safety Consultant.

"It was very interesting for me to be part of this project, because, thanks to it, I found out all about the research process, from the idea and the experiment to the publication of a paper." Louison Maurice

Job Thijssen explains the research work described in the paper.

We have investigated the mechanical properties of emulsions stabilized by micron-sized particles. Emulsions consist of droplets of a liquid dispersed in an immiscible liquid, eg water in oil. Such materials are ubiquitous in the food, personal-care, agricultural, pharmaceutical and petrochemical industries. Typically, a third component is needed to stabilize an emulsion, eg mustard in a vinaigrette of vinegar and olive oil. Conventional stabilizers tend to be surfactant molecules, ie similar to those in washing-up liquids. However, recent years have seen an increasing interest in emulsions stabilized instead by particles, known as Pickering emulsions, mainly because they feature superior functionality and shelf-life.

Mechanical properties

The mechanical properties of emulsions are crucial to their processing and use. For example, food spreads should not flow off the knife, but should spread easily onto a sandwich. The mechanical properties of particle-stabilized emulsions are not yet fully understood, as they arise from a complex interplay between the elasticity of the liquid-liquid interface at the droplet surface and interactions between the particles on that surface. Notably, we have used particles that mutually interact as hard spheres in the continuous phase under ambient conditions, ie they only repel one another upon contact. This well-defined interaction has helped us model their contribution to the mechanical properties of the corresponding Pickering emulsions.

Increased understanding

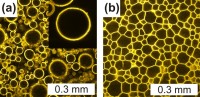

In our study, we have compressed Pickering emulsions using a centrifuge with the aim of better understanding their behaviour in mechanical equilibrium; this is also important in interpreting flow experiments on similar samples. In addition, we have developed a transparent Pickering emulsion, allowing us to characterize the structure of our samples in 3D using microscopy (see image). Finally, we can explain our data using a quantitative model in which we have incorporated interdroplet liquid films with a thickness on the scale of the particles and repulsive interactions across these films. We suggest that this repulsion between droplets is due to the energy-expensive deformation of the liquid-liquid interface between particles on one droplet due to compression against a neighbouring droplet.

Applications in porous materials

Finally, we discuss the relevance of our results to the rational design of porous materials. Using centrifugation (see image), we can squeeze our emulsions into foam-like structures, which have been suggested as templates for porous materials with applications in separation techniques, catalysis, thermal insulators, metal foams and electrodes. We can control pore size via the droplet radius, and wall thickness via the particle size and/or centrifugation speed. Moreover, the mechanical properties of these structures are crucial to their use as materials templates. For example, we have shown that changing the interactions between the particles may result in significant post-centrifugation expansion, with obvious consequences for post-processing.

The paper appears in Soft Matter, 2013,9, 7757-7765; DOI: 10.1039/C3SM51046H