DAINtech

Dispersions Arrested in Nematic (liquid crystal) technology offers a new way to create stable formulations with appealing sensory aspects without using polymers.

DAINtech is a disruptive and innovative technology for formulation scientists that solves many challenges. It:

- has excellent stability against sedimentation

- provides a unique sensory performance - highly shear thinning, yet recovers elasticity when shear ceases.

- has a tunable yield stress

- produces smooth coatings

- provides a mechanism for selective delivery of actives to surfaces

- bacteriostatic through physical, not chemical, means

- includes certain exemplars that exhibit excellent stability at high temperature

- enables formulators to avoid the use of polymer stabilisers and therefore promising to meet the EU Directive introduced on June 5th 2019.

The invention has been filed for an international patent under PCT by Edinburgh Innovations and we have a non-confidential disclosure summary.

Technology Readiness: A range of dispersions have been made in our laboratories up to 1kg using industrial colloids, including spheriglass 3000, spheriglass 5000, titania, calcite, cornflour and sunflower oil in lyotropic nematic phases with aqueous and non-aqueous solvents. We are keen to collaborate with industry to help them develop innovative and unique formulations. As a platform technology there is considerable scope for companies across a broad range of sectors to build further intellectual property on top of this license opportunity.

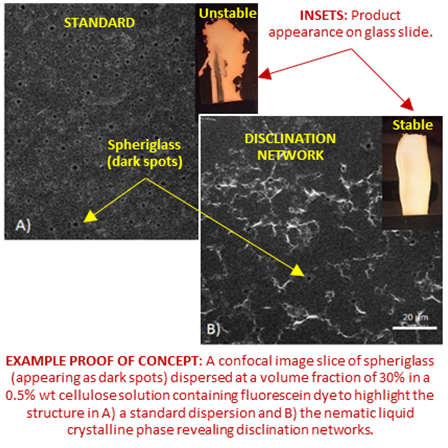

Background: The invention is related to the discovery of a stable glass phase  when colloids are dispersed at a sufficiently high volume fraction in a thermotropic nematic liquid crystal phase which was published in Science in 2011. Further research has revealed that the same behaviour can be observed for a range of particles dispersed in lyotropic nematic liquid crystal phases, including those formed by anisotropic micelles (formed with mixtures of surfactants), chromonic liquid crystals and anistotropic colloids (e.g cellulose nanocrystals and clays). Initially, it was thought that dynamic fluctuations of nematogens within a solvent, as occurs in lyotropic liquid crystals, would lead to phase separation. However, research has shown that very stable dispersions and emulsions, of particle diameters from 100nm to 50microns, can be formed when dispersing colloids in lyotropic nematic phases.

when colloids are dispersed at a sufficiently high volume fraction in a thermotropic nematic liquid crystal phase which was published in Science in 2011. Further research has revealed that the same behaviour can be observed for a range of particles dispersed in lyotropic nematic liquid crystal phases, including those formed by anisotropic micelles (formed with mixtures of surfactants), chromonic liquid crystals and anistotropic colloids (e.g cellulose nanocrystals and clays). Initially, it was thought that dynamic fluctuations of nematogens within a solvent, as occurs in lyotropic liquid crystals, would lead to phase separation. However, research has shown that very stable dispersions and emulsions, of particle diameters from 100nm to 50microns, can be formed when dispersing colloids in lyotropic nematic phases.

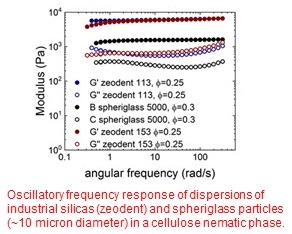

How does it work? Designed correctly, particles dispersed in a nematic phase give rise to defect lines which connect and entangle throughout the nematic phase. The defect lines carry a line tension such that the storage modulus is proportional to the number of disclination lines and viscosity is enhanced because the nematic phase becomes restricted within small monodomains. A strong gel is formed without shear, however once the gel yields, the viscosity approaches that of the background nematic phase (close to the solvent).

Please contact us if you are interested in receiving more information about this technology. We would be delighted to participate in collaborative research or consultancy with you to create a bespoke formulation for your applications, based on DAIN technology, and we are experienced in supporting companies with writing grant applications to Innovate UK and other funding bodies. Edinburgh Innovations is ready to support us with contracts, finance and funding applications.